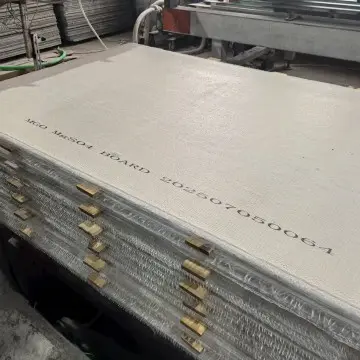

Cold-Resistant Glass Magnesium Board OEM Supplier - Trusted Factory Solutions Now Available

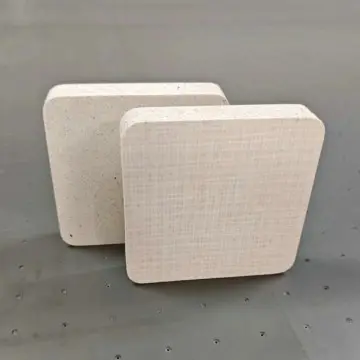

When it comes to durable building materials, the Cold-Resistant Glass Magnesium Board excels in performance and reliability. At Senchen (Tianjin) Environmental Protection Technology Co., Ltd., we offer high-quality boards designed to withstand harsh weather conditions while providing exceptional insulation. Ideal for a range of applications in construction and renovation, our products are manufactured to precise specifications as an OEM factory. We prioritize quality and sustainability, meeting and exceeding industry standards. By selecting our Cold-Resistant Glass Magnesium Board, you are ensuring the success of your projects with products that deliver unparalleled durability and performance. Quality and reliability are just a call away!Best Methods To Cold-Resistant Glass Magnesium Board Pioneers in the Field Service Backed by Expertise

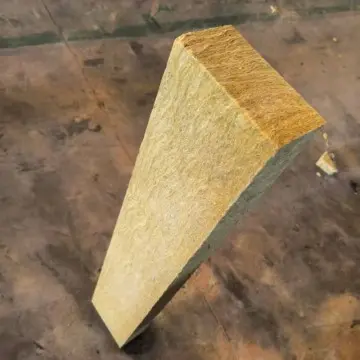

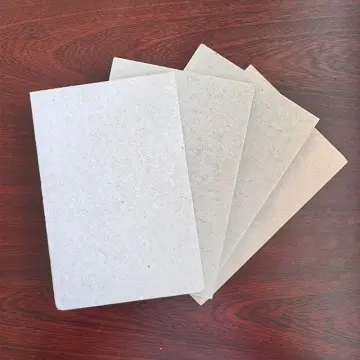

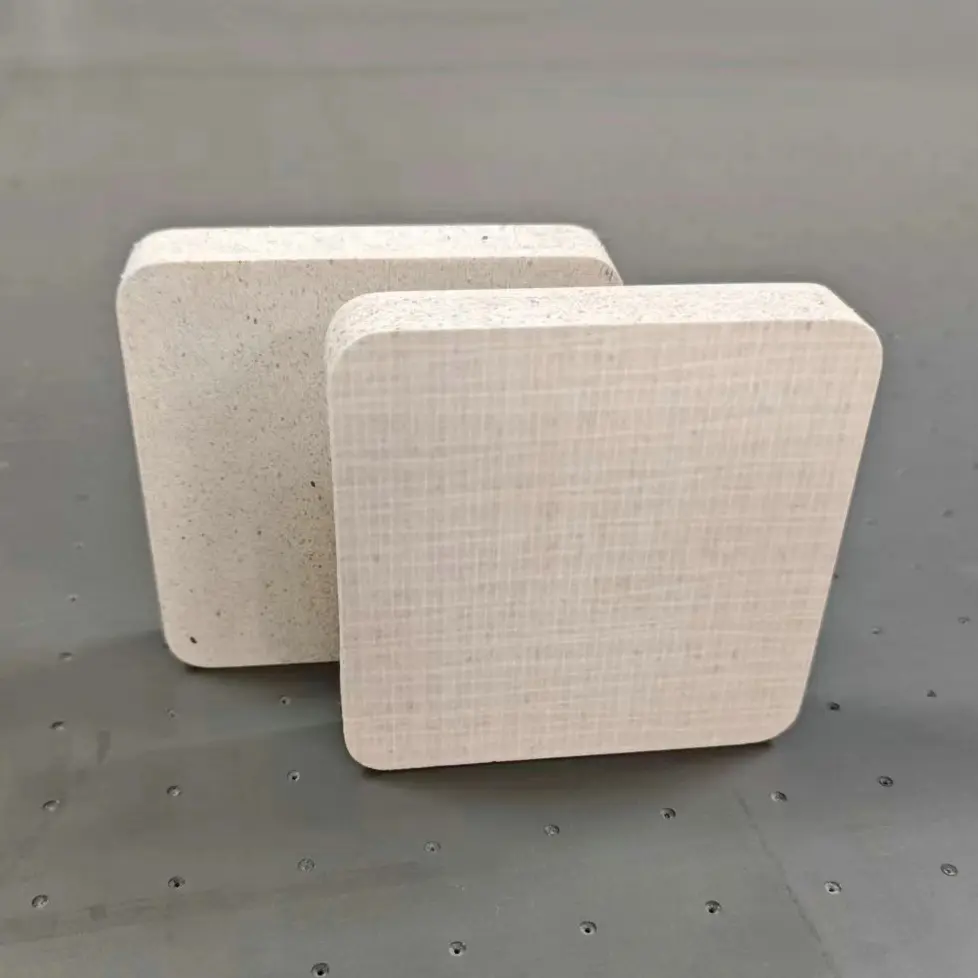

In the evolving landscape of construction materials, Cold-Resistant Glass Magnesium Boards are emerging as a game changer for both residential and commercial applications. Emphasizing durability and insulation, these boards effectively combat extreme weather conditions, making them an essential choice for structures in colder climates. Leading experts in the field advocate for utilizing advanced manufacturing techniques that enhance the boards' resistance to moisture and temperature fluctuations, ensuring longevity and performance. The unique composition of glass magnesium boards, which incorporates magnesium oxide, contributes to their lightweight yet robust characteristics. This feature simplifies handling during installation, reducing labor costs and time on-site. Additionally, their non-combustible nature promotes safety, aligning with modern building regulations and environmental standards. Adopting these innovative materials is not just about following trends; it’s about investing in sustainable solutions that promise energy efficiency and lower maintenance needs. For global purchasers, the integration of Cold-Resistant Glass Magnesium Boards into their supply chain represents a forward-thinking approach to building design and construction. By collaborating with manufacturers who prioritize sustainability and possess extensive technical expertise, buyers can ensure they are adopting the best practices in material selection that will stand the test of time in any climate. As the industry moves toward greener alternatives, embracing these advanced materials will play a crucial role in shaping the future of construction.

Best Methods To Cold-Resistant Glass Magnesium Board Pioneers in the Field Service Backed by Expertise

| Method | Description | Benefits | Expertise Level |

|---|---|---|---|

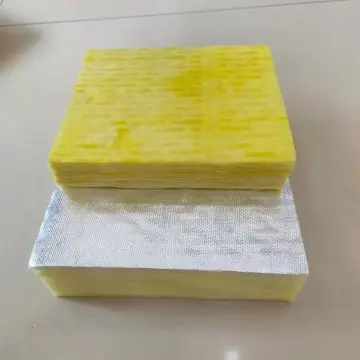

| Thermal Insulation | Utilizing advanced Thermal Insulation techniques to enhance glass magnesium board performance in cold environments. | Reduced heat loss, improved energy efficiency. | Advanced |

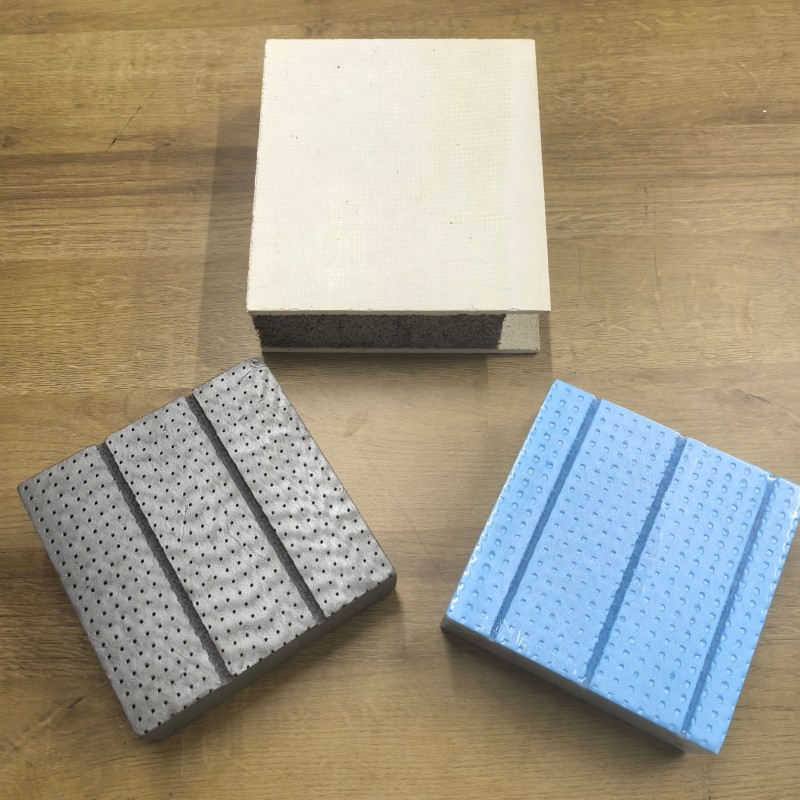

| Surface Treatment | Applying specialized coatings to enhance cold resistance and durability of the boards. | Increased lifespan, reduced maintenance costs. | Intermediate |

| Reinforced Frame | Incorporating a reinforced frame structure to support the glass magnesium board in extreme cold conditions. | Enhanced structural integrity, improved safety. | Expert |

| Heat Retention | Designing boards with heat-retention characteristics to improve energy efficiency. | Lower energy bills, better temperature control. | Basic |

| Moisture Barrier | Implementing moisture barrier strategies to prevent frost and ice accumulation. | Improved durability, enhanced user safety. | Intermediate |

Champions of Cold-Resistant Glass Magnesium Board Global Reach Factory-Direct Excellence

L

Lucas Martinez

Excellent quality! Their customer service team was professional, friendly, and always ready to assist with inquiries.

27 June 2025

E

Ethan Nelson

I can wholeheartedly recommend this product. The quality is excellent, and their support team is very professional.

30 June 2025

S

Samuel Torres

This is a fantastic product! I was impressed by the professionalism of the support staff when I needed assistance.

23 June 2025

E

Emily Torres

I thoroughly enjoy using this product! The follow-up customer service was professional and sincere.

04 July 2025

H

Henry Martinez

Superb product! The follow-up support was prompt and quite professional.

11 May 2025

E

Elliot Young

Great product! The after sales staff are knowledgeable and genuinely care about their customers.

18 May 2025

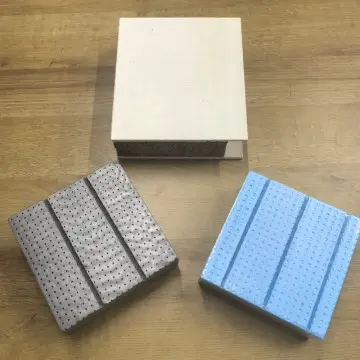

Environmental Building Board

Environmental Building Board Fire-proof Board

Fire-proof Board Sound Resistance

Sound Resistance Termite Resistance

Termite Resistance