Wholesale Construction Panels: Supplier Insights & Manufacturing Expertise

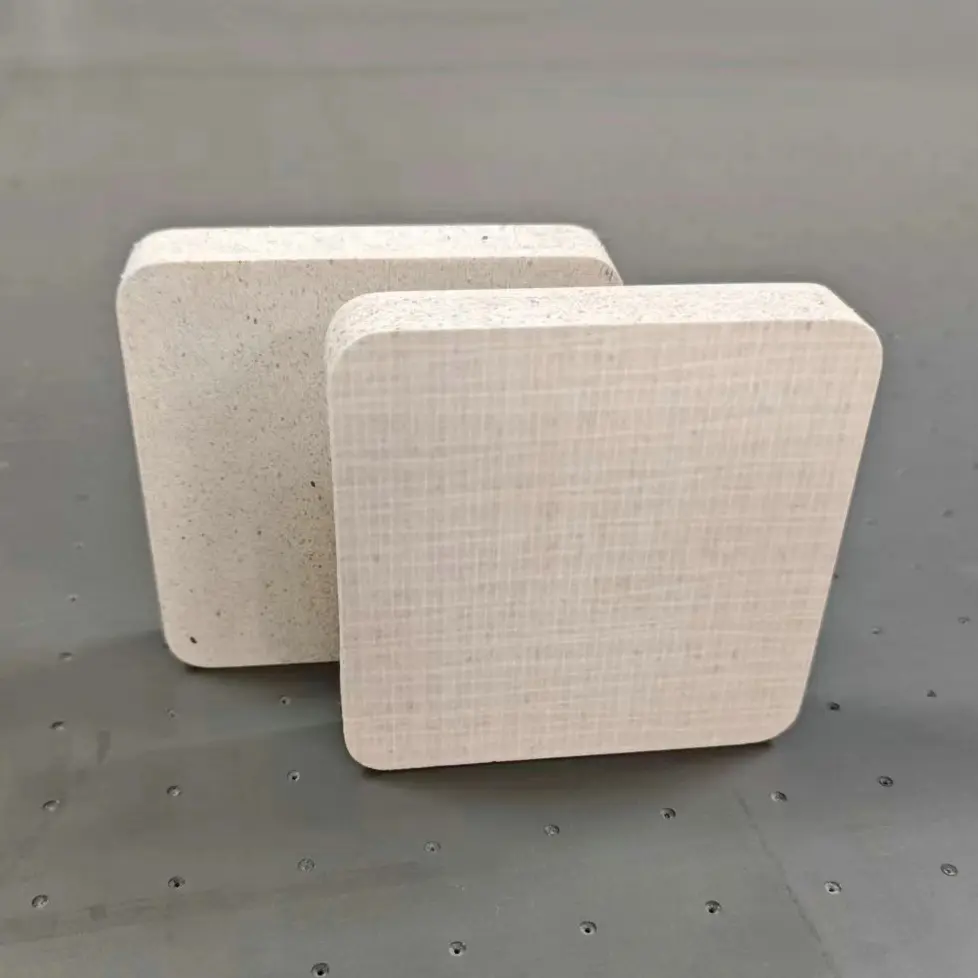

At Senchen (Tianjin) Environmental Protection Technology Co., Ltd., we prioritize quality and reliability in our Construction Panels. With CE Certification, our panels adhere to the highest safety and environmental standards, providing you the assurance you need for your projects. Manufactured in our advanced factory, these panels are crafted from durable and sustainable materials and can be tailored to meet your specific requirements, whether for residential, commercial, or industrial applications. Partnering with us means you benefit from exceptional products and dedicated support throughout your purchasing journey. Reach out to discuss how we can enhance your next project with our reliable Construction Panels.Methods To Construction Panel For the Current Year Ahead of the Curve

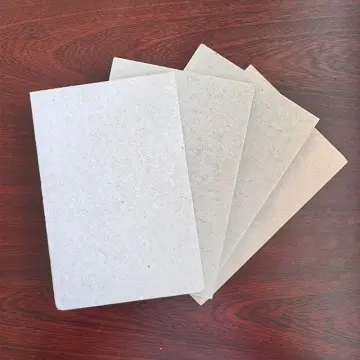

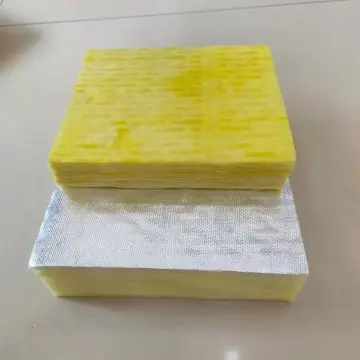

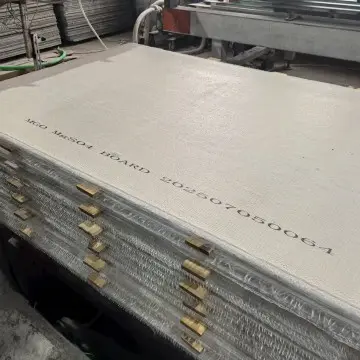

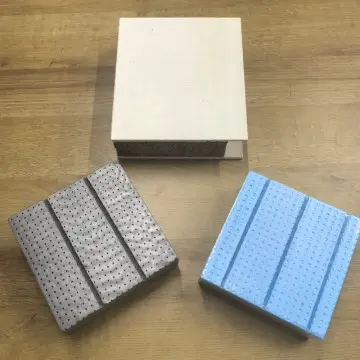

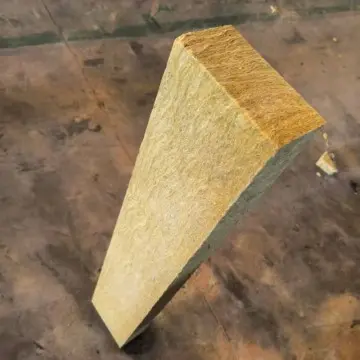

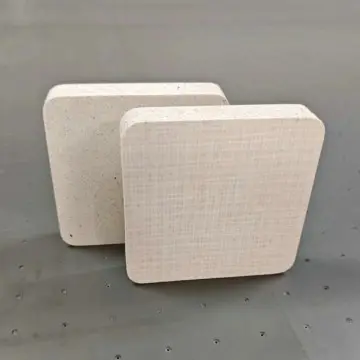

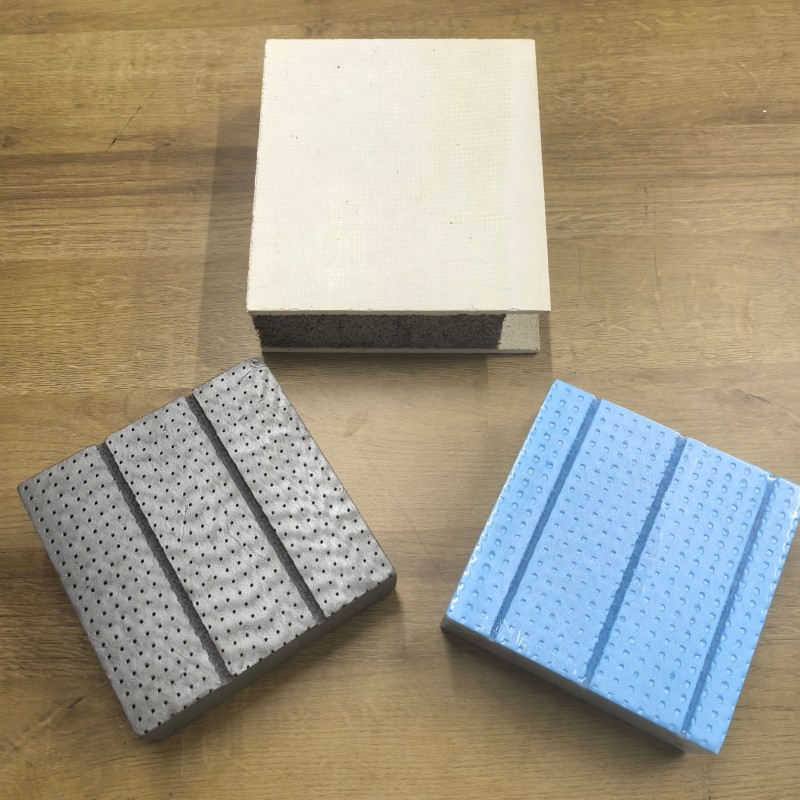

In the ever-evolving construction materials market, it's crucial for global buyers to stay ahead of the curve by exploring innovative methods for panel construction. As the demand for sustainable and efficient building solutions rises, materials such as magnesium oxide (MGO) boards, Calcium Silicate Boards, cement fiber boards, and insulation options like glass wool and rock wool are becoming essential components in modern construction projects. These materials not only meet international standards for durability and fire resistance but also contribute to energy efficiency, helping builders and architects design eco-friendly structures. One effective method gaining traction is the integration of modular panel systems. These systems allow for rapid assembly and disassembly, reducing onsite construction time and minimizing waste. With the versatility of materials like MGO and Calcium Silicate Boards, these modular solutions can be tailored to meet specific structural requirements, making them ideal for a variety of applications, from residential homes to large commercial buildings. Additionally, the lightweight nature of these panels offers ease of transportation and handling, further streamlining the construction process. Furthermore, leveraging advanced technologies such as Building Information Modeling (BIM) can enhance project planning and execution. By simulating the construction process digitally, teams can optimize material usage, reduce errors, and improve collaboration among stakeholders. As global procurement professionals look for ways to innovate their construction approaches, adopting these methods can lead to significant cost savings and improved project outcomes in the year ahead. Embracing these modern materials and techniques will position builders at the forefront of the industry, ensuring their projects are not only competitive but also sustainable in the long run.

Methods To Construction Panel For the Current Year Ahead of the Curve

| Method | Description | Expected Outcomes | Implementation Timeline |

|---|---|---|---|

| Modular Design | Utilizing pre-fabricated components for faster assembly | Reduced construction time and costs | 3-6 months |

| Sustainable Materials | Using recycled and eco-friendly materials in construction | Increased energy efficiency and reduced carbon footprint | Ongoing |

| Digital Twin Technology | Creating a virtual model for planning and management | Enhanced project monitoring and risk management | 6-12 months |

| 3D Printing | Using additive manufacturing for construction elements | Lower material waste and faster production | 1-3 months |

| Lean Construction | Minimizing waste and maximizing value on-site | Improved resource management and task efficiency | Ongoing |

Proven Methods To Construction Panel Delivers Unmatched Quality in 2025

O

Oliver Adams

Impressive service overall! Quality is fantastic, and the after-support team is highly knowledgeable.

09 June 2025

S

Samuel Torres

This is a fantastic product! I was impressed by the professionalism of the support staff when I needed assistance.

23 June 2025

D

David Evans

Excellent quality and fantastic after-sales support! Every interaction was handled with professionalism.

19 June 2025

A

Aiden Carter

Quality is excellent! And the level of support I received afterward was impressively professional.

27 June 2025

E

Evelyn Smith

Great experience! Product quality is solid, and the support team is responsive and check-ins are appreciated.

20 May 2025

J

James Lee

High-quality product! The level of care and professionalism in the support team was quite impressive.

25 May 2025

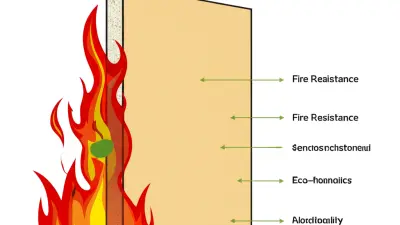

Environmental Building Board

Environmental Building Board Fire-proof Board

Fire-proof Board Sound Resistance

Sound Resistance Termite Resistance

Termite Resistance