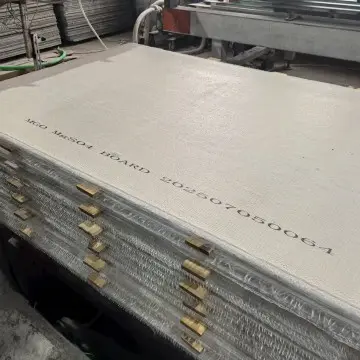

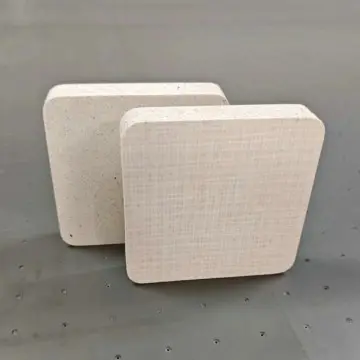

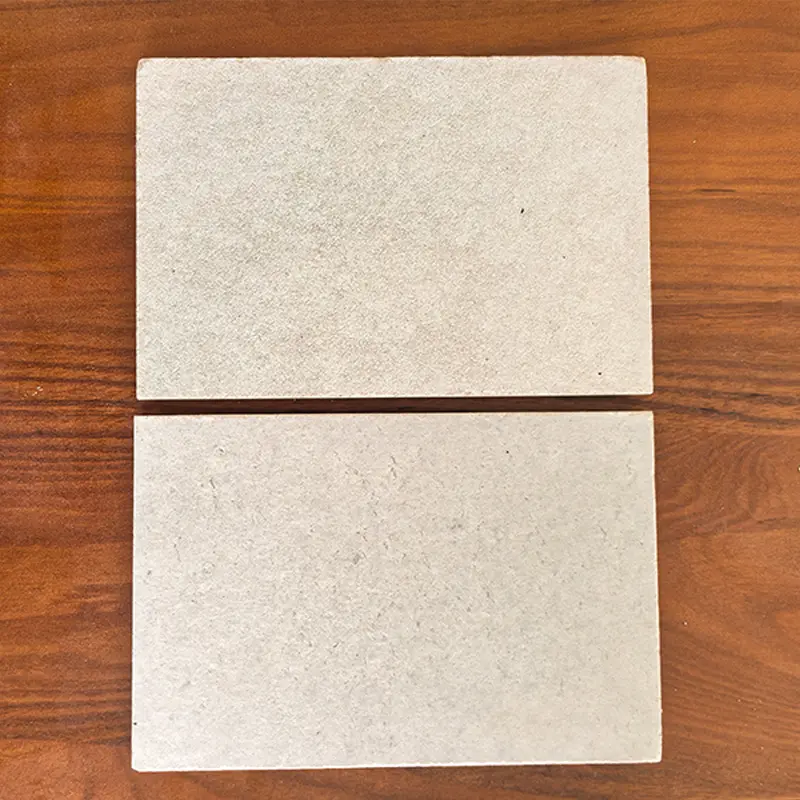

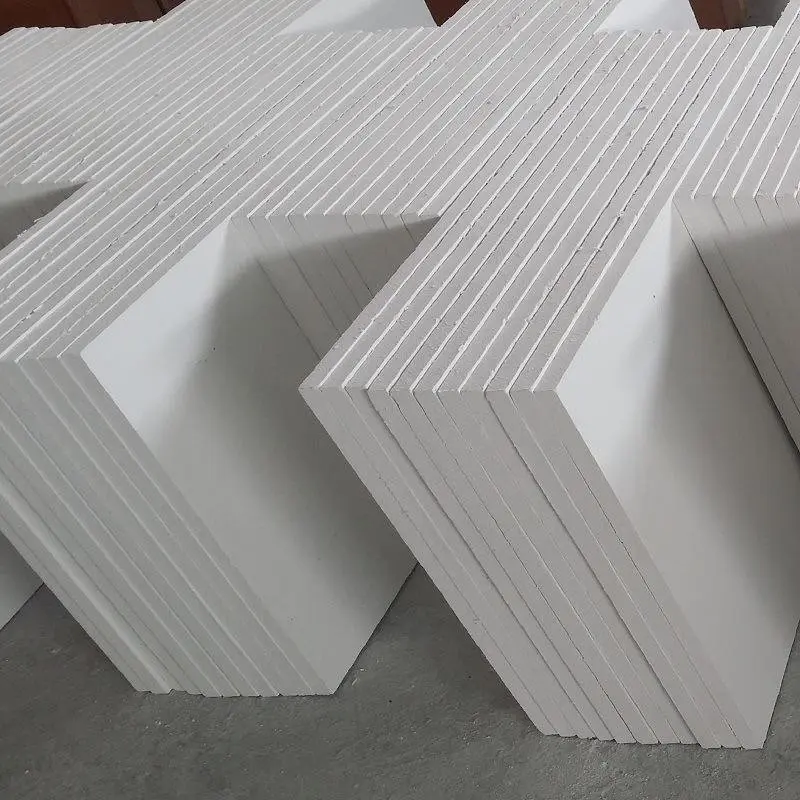

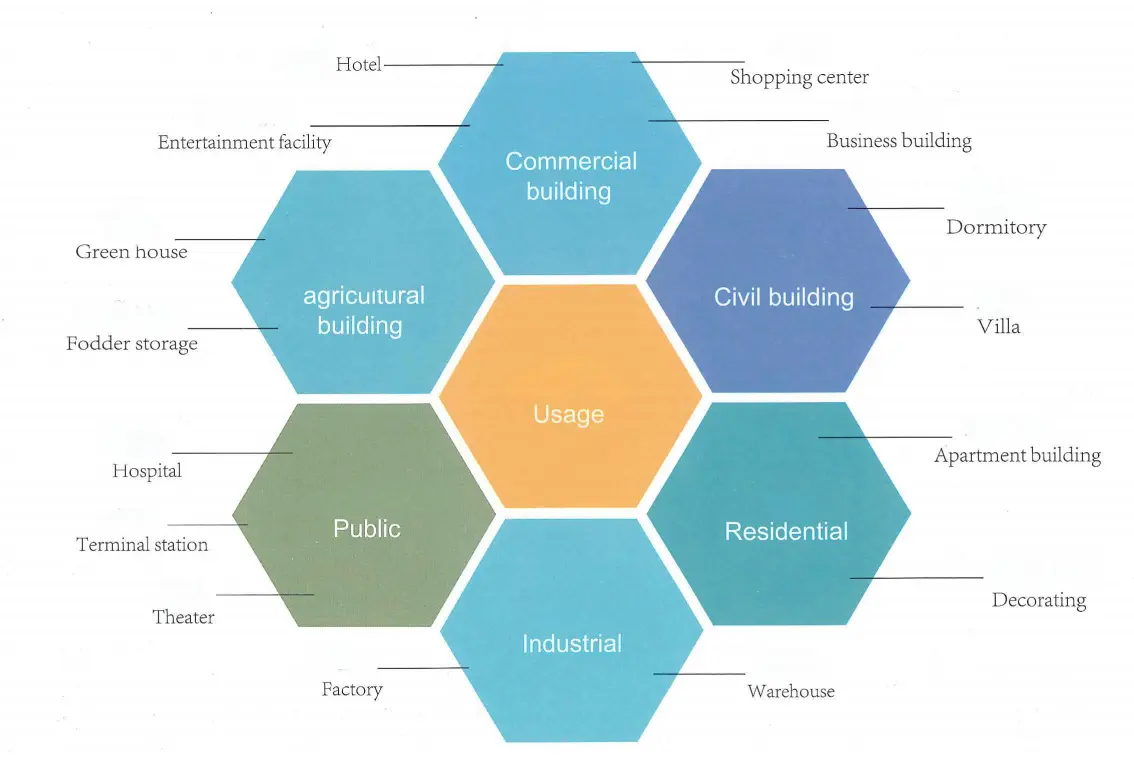

Forest Calcium Silicate Board for wide building application

-

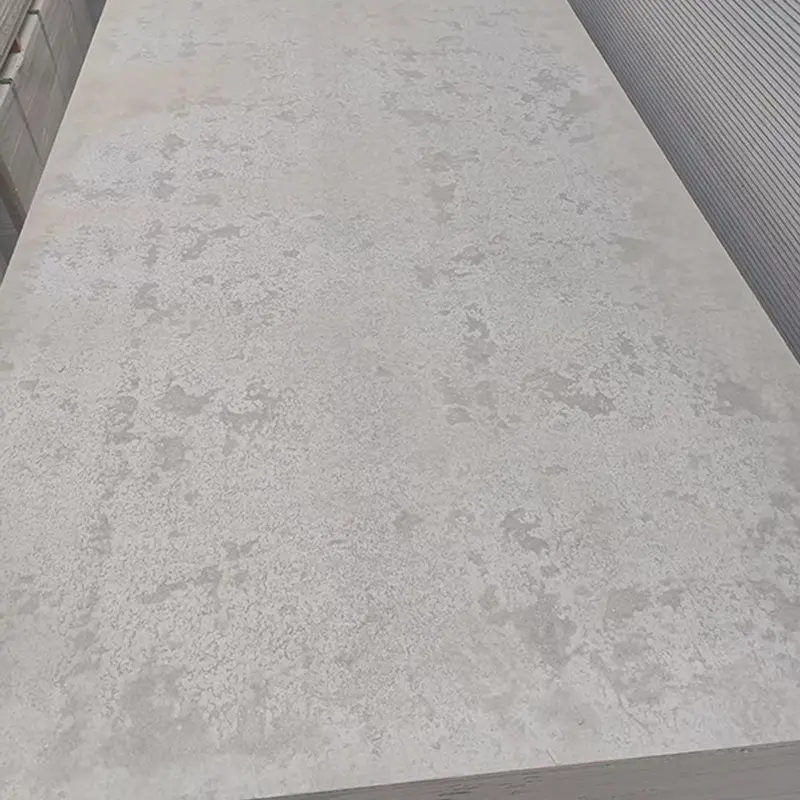

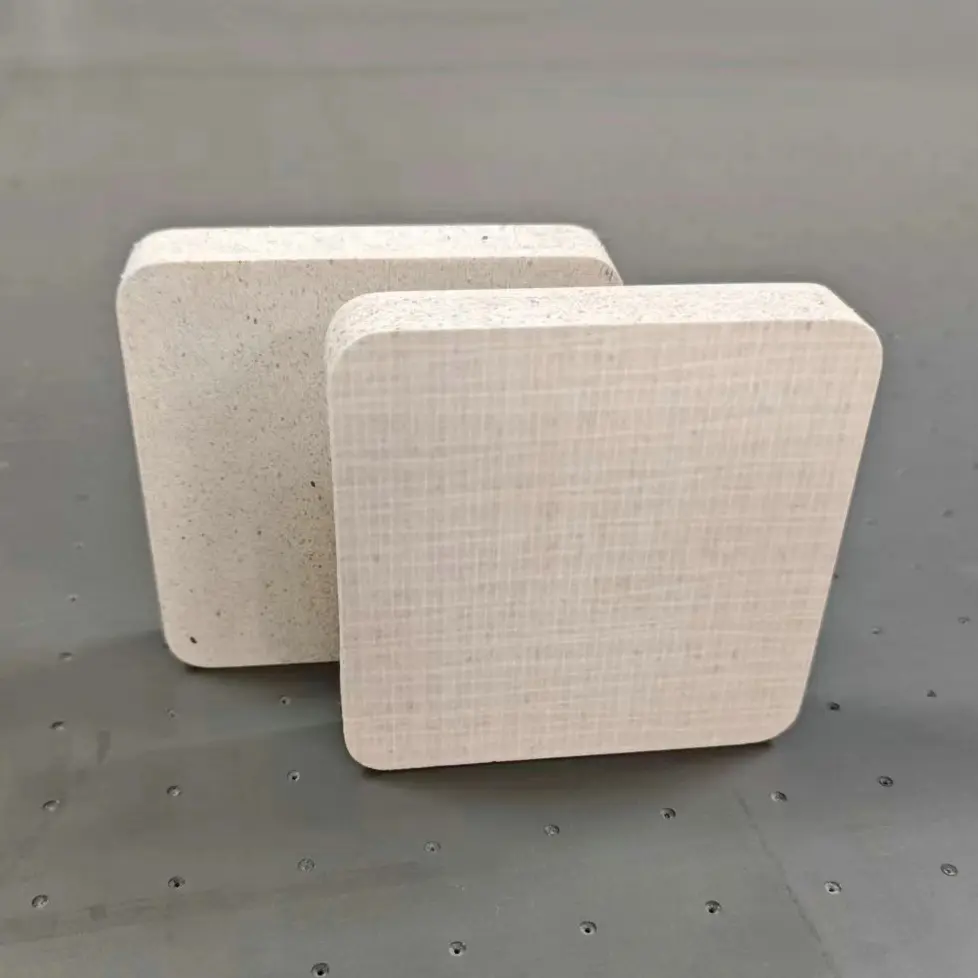

Excellent fire resistance

Non-combustible class A material

-

Superior water proofing ability

Good moisture resisting ability, not easy to generate swelling or shaping.

-

High Strength

The wall of Calcium Silicate board is very strong and durable, not easy to be damaged.

-

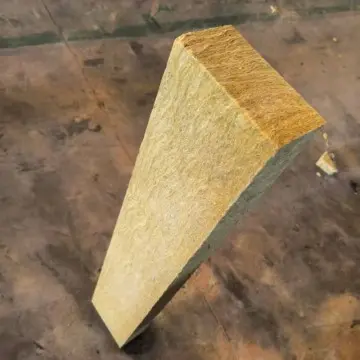

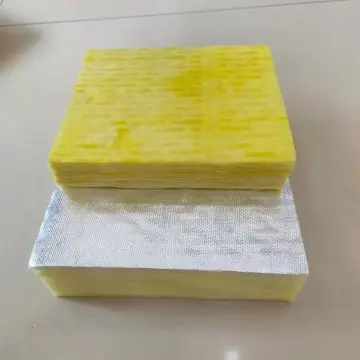

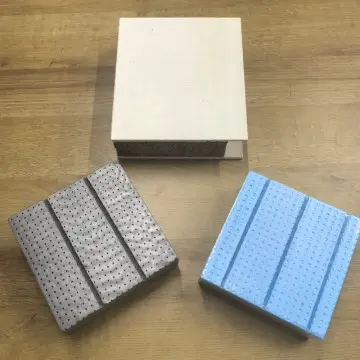

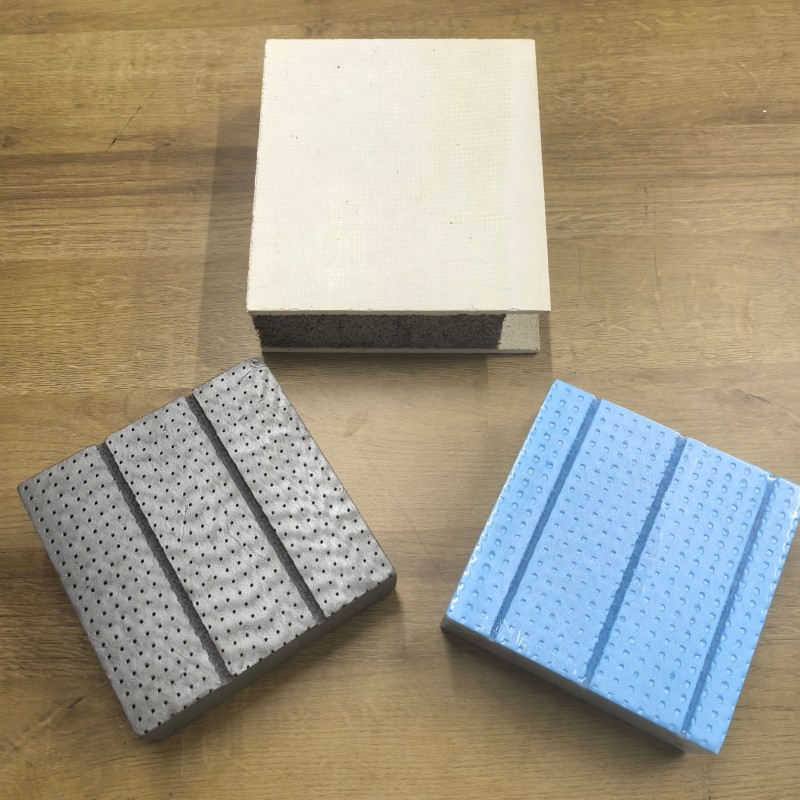

Wonderful sound and heat insulation performance

Filled with mineral wool, not only heat insulation but also sound insulation

-

Stable Dimensions

Both moisture movement and the shrinking percentage are controlled in a optimum range.

| Rupture strength(MPa) | Non inflammability | Moisture Expansion Rate(%) | |

| Standard Request | ≥4 | A1 | ≤0.25 |

| Testing result | 8.1 | A1 | 0.19 |

| Determined | Pass | Pass | Pass |

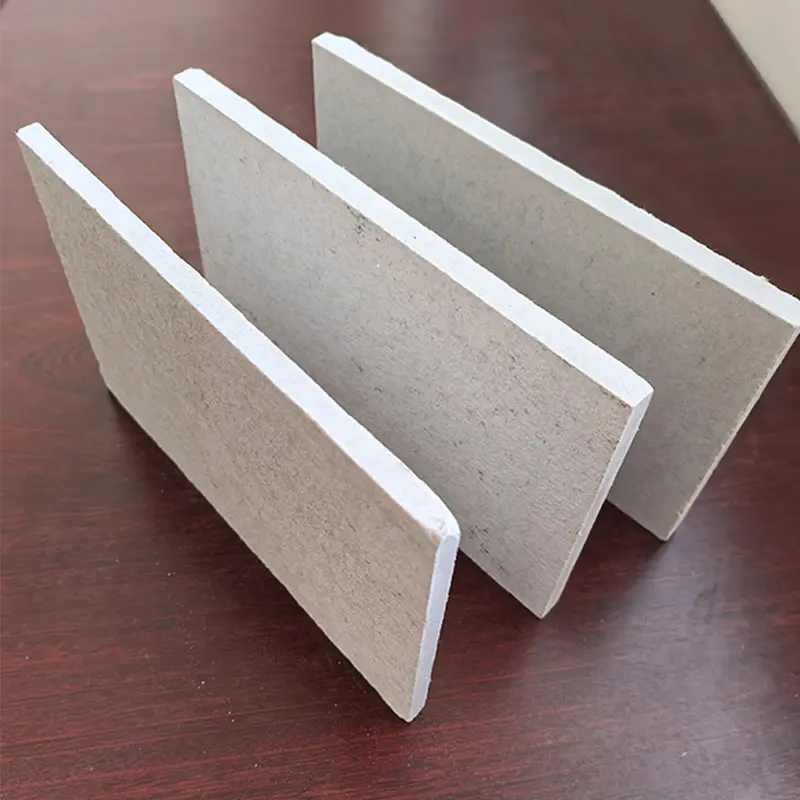

| Thickness(mm) | Density | L×W(mm) | Surface treatment |

| 4 - 25 | Common type: 1.2–1.5 g/cm³

High-density type: 1.6–2.0 g/cm³ |

2400×1200 Customized available | Non-belt sanded; belt sanding on the front side is optional.

Front side belt sanded; chamfering is optional. |

● Can be used for the uneven wall surface.

● Can add different heat insulation into the empty space of this system. Recommend you to use the mineral wool in 50 - 100kg/m².

● Can arrange the pipes and lines in the interior of protection wall.

● It will have special visual after the well treatment of the wall.

● Our board will be dehydrated before delivery, so we should place it on the flat dry warehouse ground.

● Each pallet of them should be covered with the tarpaulin or put into the nylon bag.

● In the storage place of our products, the edges and angles should be avoided being damaged by the automatic and artificial operations.

● Can not put the boards vertically.

● The height for each pallet of products is 1.2m; if you want to pile up the pallets then the total height of them should be less than 3.0m

Environmental Building Board

Environmental Building Board Fire-proof Board

Fire-proof Board Sound Resistance

Sound Resistance Termite Resistance

Termite Resistance