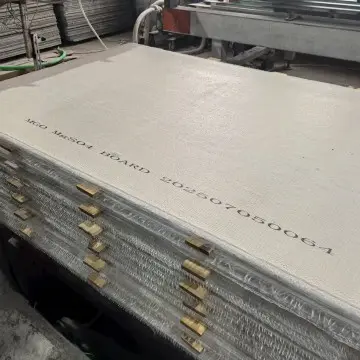

Magnesium Oxide Boards (MgO Boards)

1. Core Parameters

|

Density |

950 - 1150 kg/m³ (59 - 72 lb/ft³) - Optimized for strength-to-weight ratio |

|

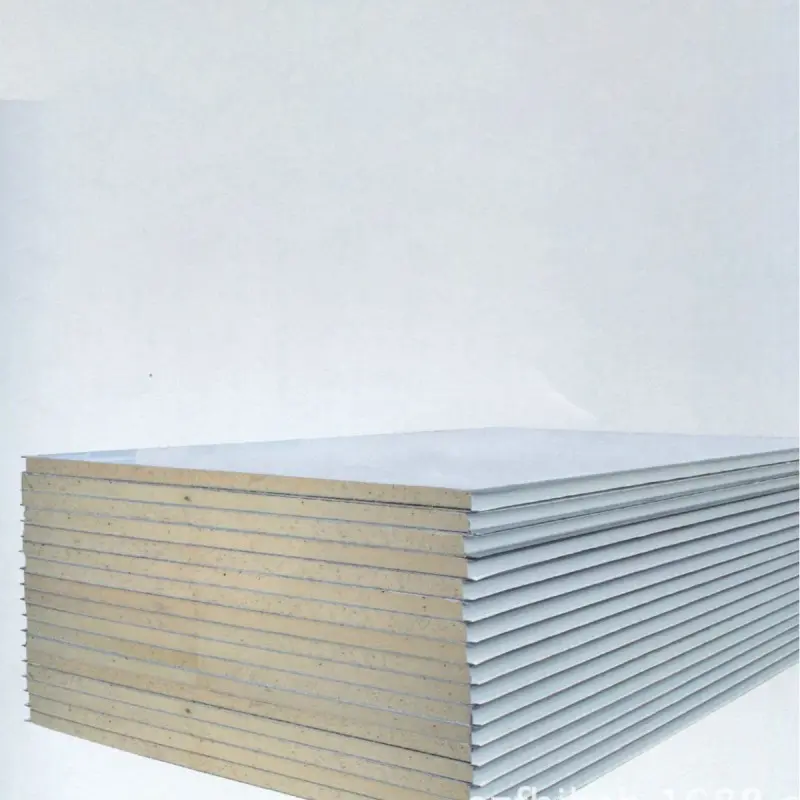

Thickness |

6mm, 8mm, 9mm, 12mm, 15mm, 18mm, 20mm (Custom thickness available). |

|

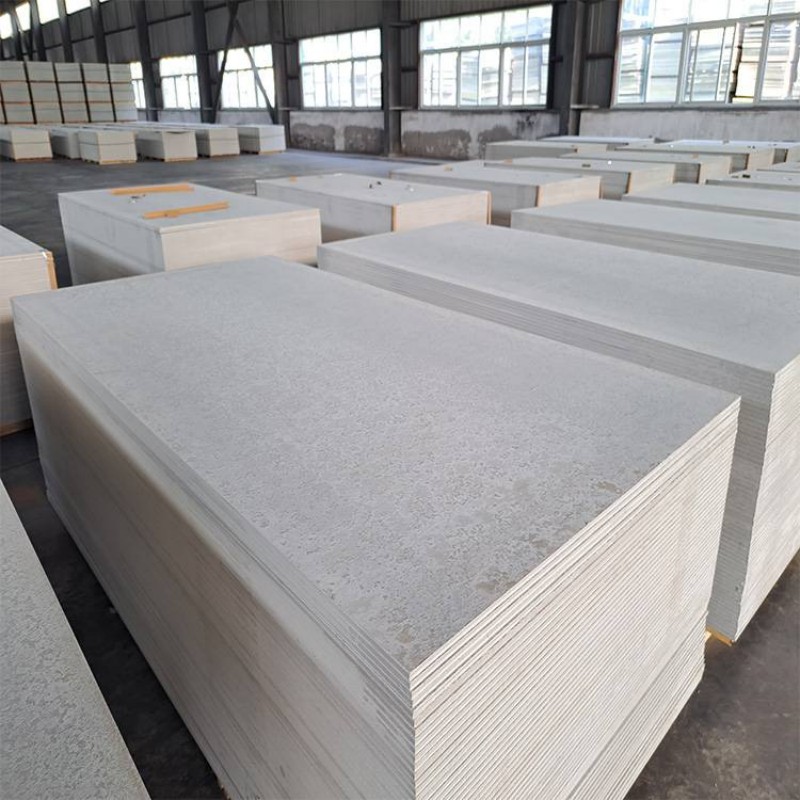

Size |

1220mm x 2440mm (4' x 8'), 1200mm x 2400mm. (Custom sizes possible). |

|

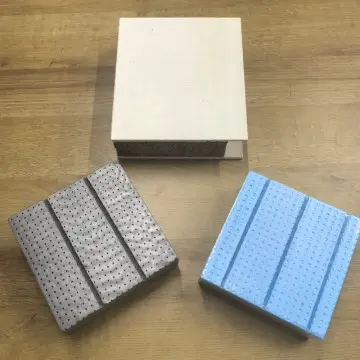

Color |

Natural off-white/light gray |

2. Fire Performance (A1 Grade)

|

Fire Reaction |

A1 |

|

Flame Spread |

Zero flame spread (ASTM E84 / UL 723: Class A) |

|

Smoke Developed Index (SDI) |

< 5 (ASTM E84 / UL 723) |

|

Heat Release |

Total Heat Release (THR) and Peak Heat Release Rate (PHRR) |

|

Toxicity |

Zero |

3. Mechanical Strength & Durability

| Flexural Strength | ≥ 15 MPa (EN 12467) |

| Modulus of Elasticity | ≥ 4500 MPa (EN 12467) |

| Impact Resistance | High resistance to impact damage |

| Screw Holding Capacity | Meets or exceeds relevant building standards |

| Nail Pull Resistance | ≥ 75 lbf (340 N) (ASTM C473) |

| Thermal Shock Resistance | Exceeding 1000°C without spalling or crackin |

4. Moisture & Environmental Resistance

| Water Resistance | < 10% by weight after 24h immersion (EN 12467) |

| Moisture Vapor Transmission | Allows walls to "breathe" |

| Freeze-Thaw Resistance | Excellent performance after multiple cycles (ASTM C666) |

| Mold & Mildew Resistance | Inherently inorganic core inhibits growth (ASTM G21, ASTM D3273) |

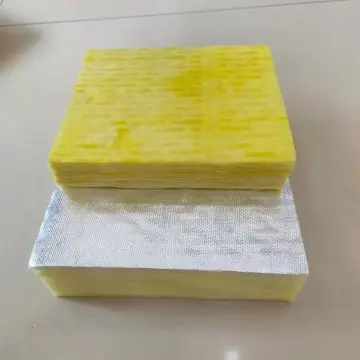

5. Thermal & Acoustic Properties:

Thermal Conductivity (λ): ~0.15 - 0.20 W/(m·K) - Provides basic insulation.

Acoustic Performance: Contributes to sound reduction in wall/ceiling assemblies (STC ratings vary by system design).

6. Environmental & Health:

VOCs: Zero VOC emissions (tested per ISO 16000, AgBB).

Formaldehyde: Free (< Detection Limit - EN 717-1, JIS A 1460, ASTM E1333).

Asbestos & Heavy Metals: Free (tested per relevant international regulations).

Recyclability: Inherently recyclable mineral content.

Sustainable Sourcing: Primary raw materials from abundant natural minerals.

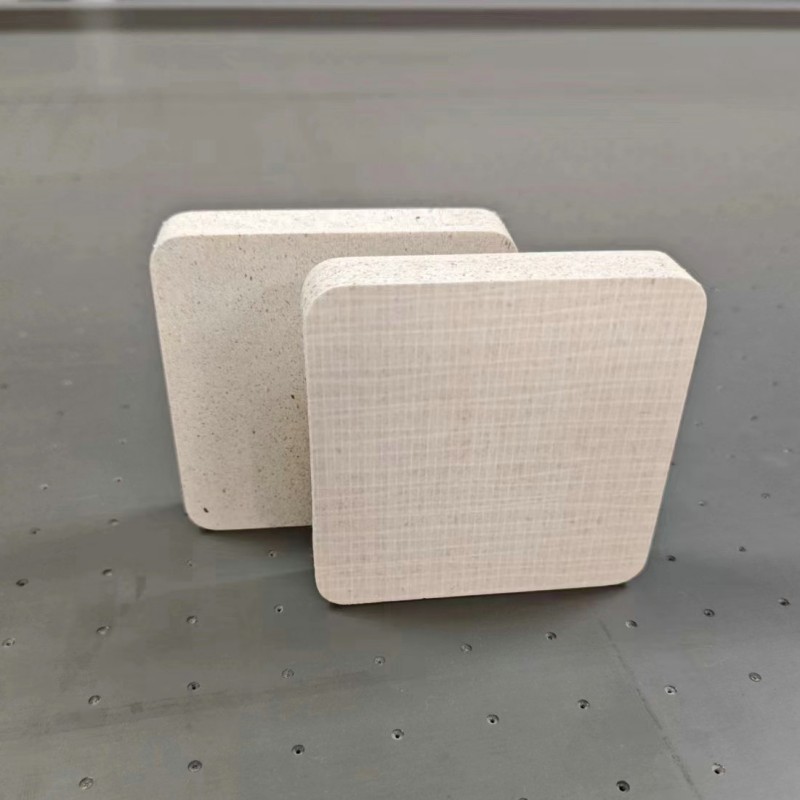

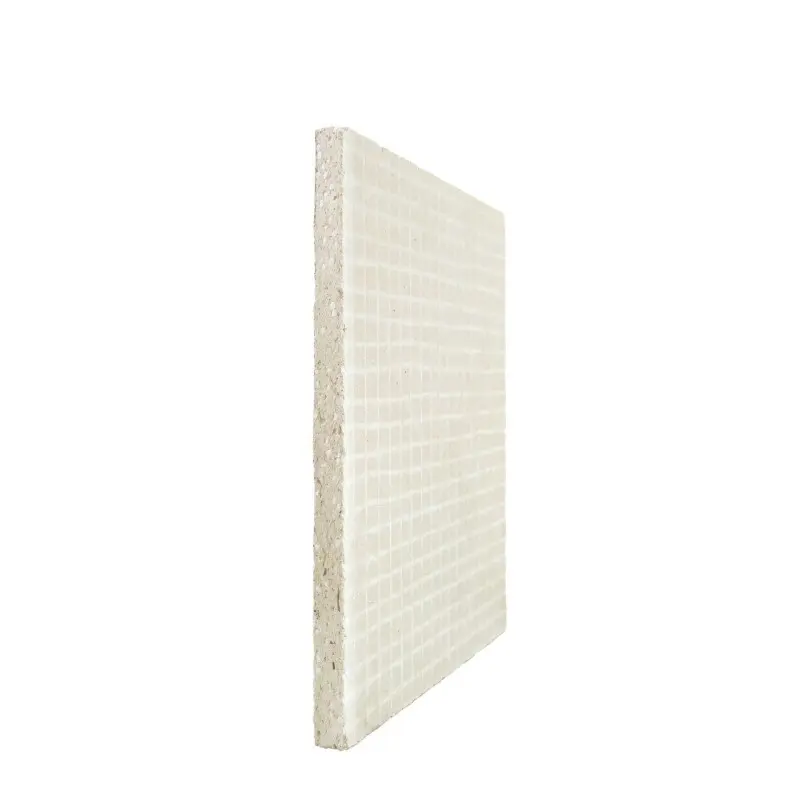

7. Surface & Workability:

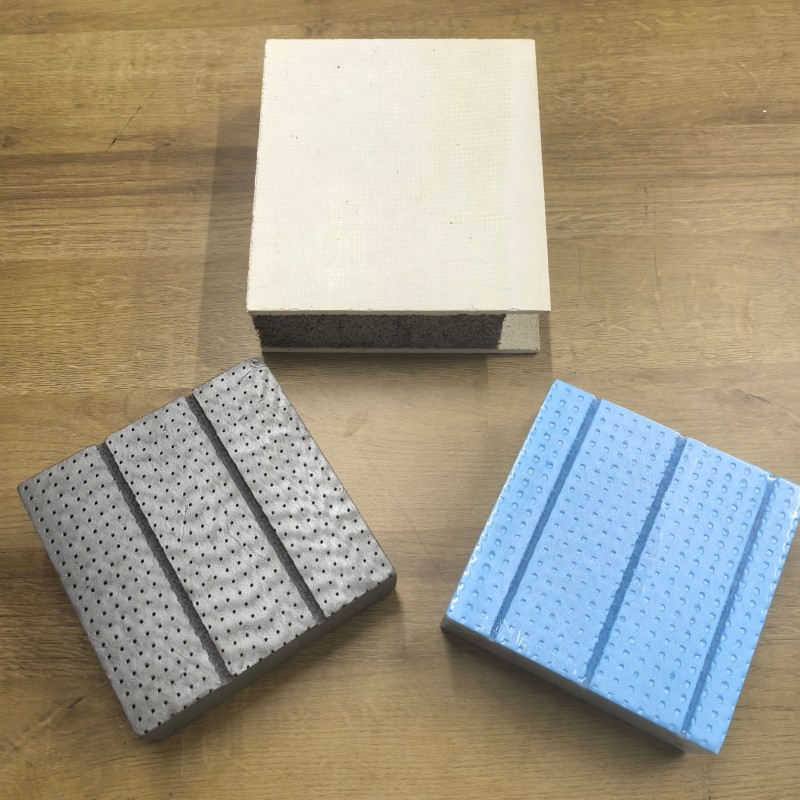

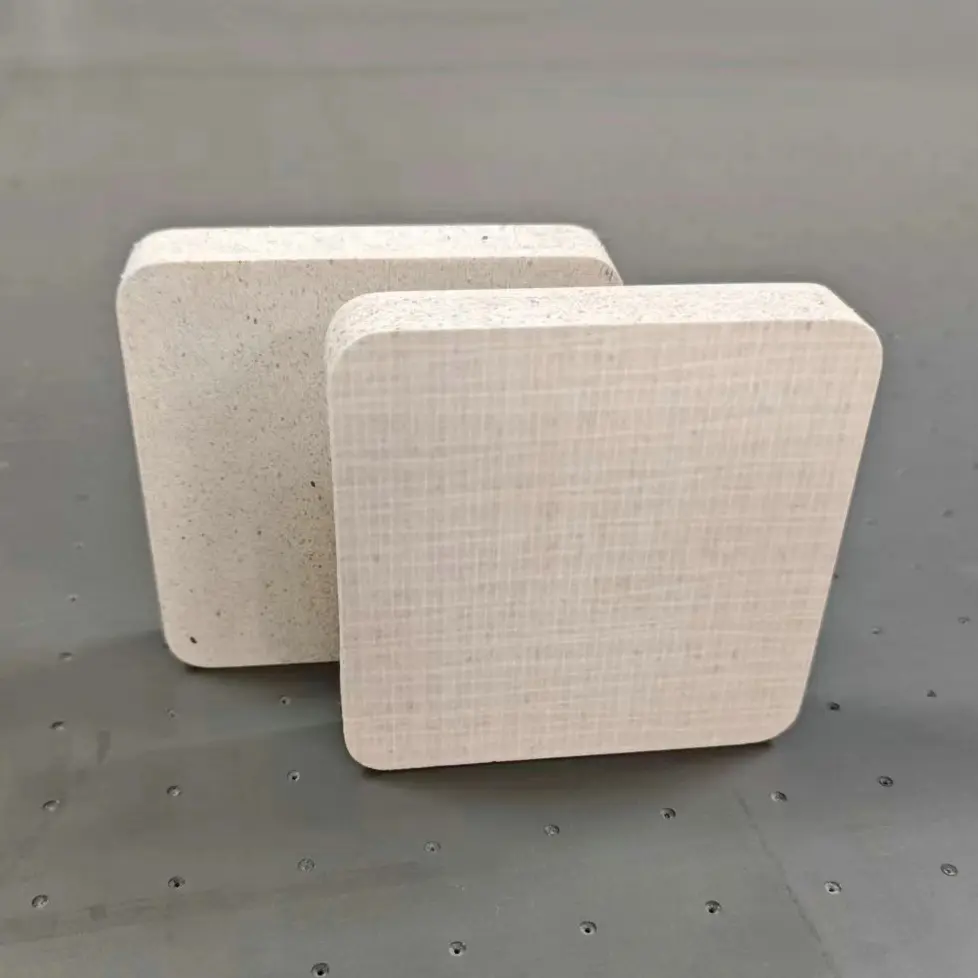

Surface Finish: Smooth, low-dust factory finish ("PureGuard Treated" for improved adhesion).

Machinability: Easily cut, routed, drilled, and shaped with standard woodworking tools (minimizes silica dust vs. cement boards).

Adhesion: Excellent substrate for direct application of tiles, renders, plasters, paints, and veneers.

8. Certifications & Compliance (Examples - Specific to Manufacturer):

Fire: EN 13501-1: A1, ASTM E84 Class A, BS 476 Parts 4, 6, 7, 11, UL Certification (System dependent).

Structural: EN 12467, ASTM C1288 / C1325.

Environment/Health: LEED contributable, GREENGUARD Gold (or equivalent), EPDs (Environmental Product Declarations).

Quality: ISO 9001.

Fire-rated partitions, shafts, and ceilings (EI Systems).

Structural sheathing & subflooring (where fire rating required).

External sheathing / Backer board for ventilated facades & renders.

Fire protection for structural steel (column/wrap systems).

Fire-rated doors & access panels.

Modular construction core material.

Moisture-resistant linings (bathrooms, basements - where specified).

Environmental Building Board

Environmental Building Board Fire-proof Board

Fire-proof Board Sound Resistance

Sound Resistance Termite Resistance

Termite Resistance