Comparing Magnesium Sulfate and Magnesium Chloride Boards, as well as Non-woven and Sanded Magnesium Oxide Boards

In the world of construction materials, magnesium oxide (MGO) boards have gained significant popularity due to their desirable properties such as fire resistance, strength, and versatility. Among the various types of MGO boards, magnesium sulfate boards and magnesium chloride boards stand out, each with its own unique characteristics. Additionally, non-woven and sanded Magnesium Oxide Boards also offer different features that make them suitable for specific applications. In this article, we will delve into the comparisons between these types of boards to help you make an informed decision for your next project.

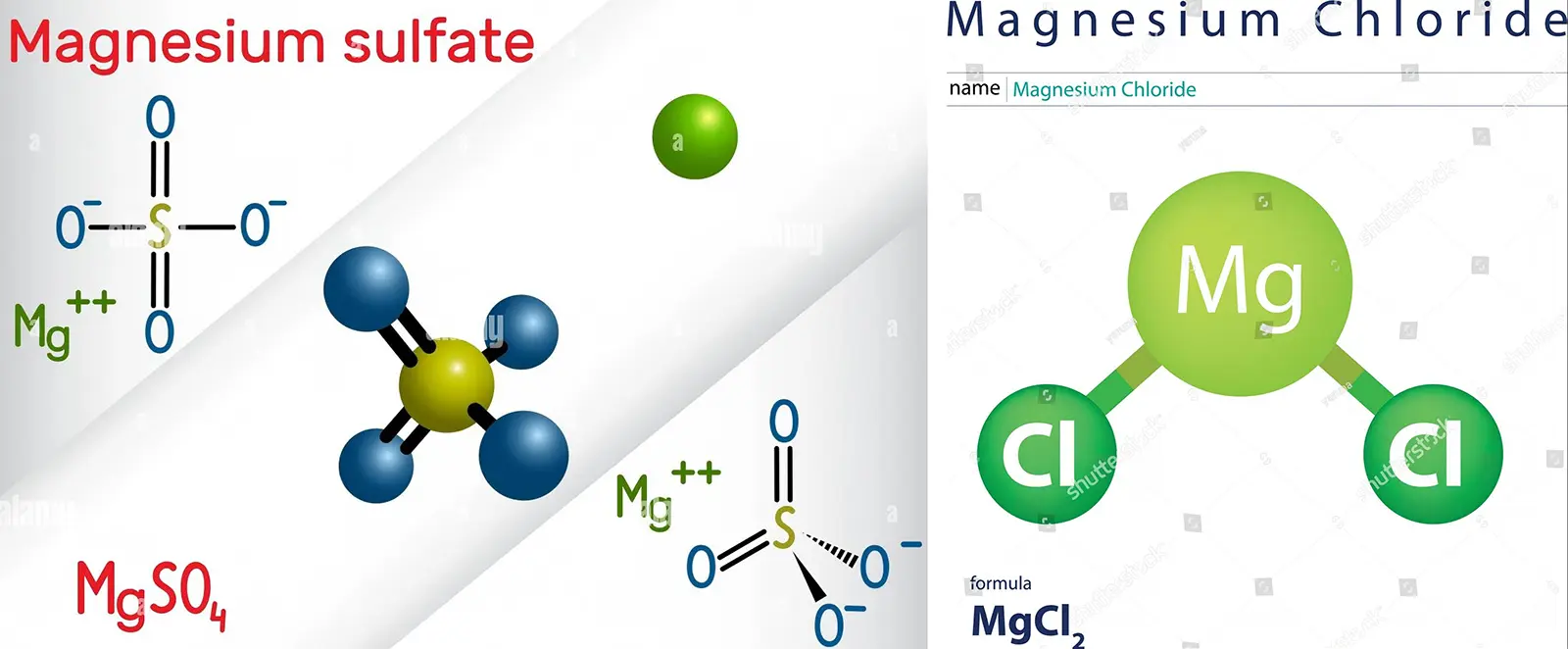

Magnesium Sulfate Boards vs. Magnesium Chloride Boards

Raw Material Composition

● Magnesium Chloride Boards: These boards primarily consist of magnesium oxide (MGO) and magnesium chloride (Mg Cl₂). Magnesium oxide serves as the binding material, combined with reinforcing fibers and other fillers.

● Magnesium Sulfate Boards: The main components are magnesium oxide (MGO) and magnesium sulfate (Mg SO₄). By replacing magnesium chloride with magnesium sulfate, magnesium sulfate boards are more suitable for use in humid environments.

Water Resistance

● Magnesium Chloride Boards: Due to the presence of magnesium chloride, these boards are prone to deliquesce (absorbing moisture) when exposed to water. This can lead to a decrease in strength, making them unsuitable for prolonged exposure to moisture. In fact, their water absorption rate can be relatively high, often reaching around 15 - 20% in high - humidity conditions.

● Magnesium Sulfate Boards: Thanks to the stability of magnesium sulfate, these boards have a low water absorption rate, typically below 10%. This makes them highly moisture - resistant and ideal for use in relatively humid environments such as bathrooms, kitchens, and exterior walls in areas with high humidity. [Insert a graph here showing the water absorption rate comparison of magnesium sulfate boards and magnesium chloride boards over time]

Fire Resistance

Both magnesium sulfate and magnesium chloride boards exhibit excellent fire resistance. As magnesium - based materials, they have a high melting point, providing good fire protection. They are often classified as non - combustible materials, meeting strict fire safety standards. For example, they can withstand temperatures of up to 1200°C without significant degradation, making them suitable for use in fire - rated partitions and ceilings.

Corrosion Resistance

● Magnesium Chloride Boards: Chloride ions in these boards can corrode metals such as steel, nails, and studs. This poses potential risks when used in steel - framed structures. In a study, when steel studs were in contact with magnesium chloride boards for six months in a humid environment, significant corrosion was observed on the surface of the steel.

● Magnesium Sulfate Boards: Free of chloride ions, these boards are more metal - friendly and show better corrosion resistance. They can be safely used in applications where contact with metal components is inevitable, such as in industrial buildings with metal frameworks.

Application Scenarios

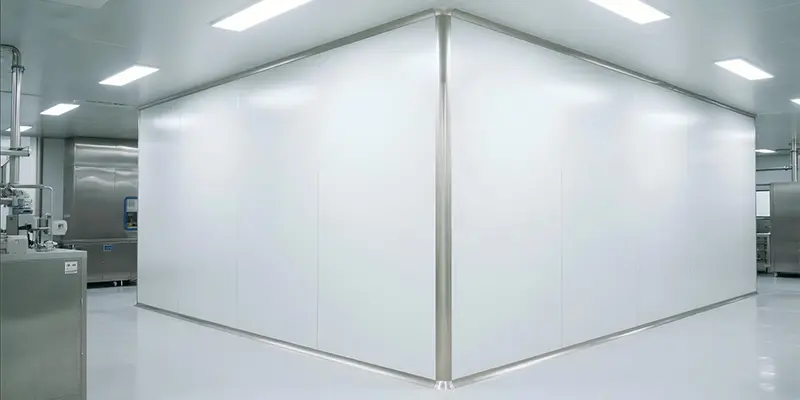

● Magnesium Chloride Boards: These are suitable for Wall Panels, ceilings, and interior wall decorations in relatively dry environments. However, they are generally not recommended for use in humid areas or scenarios that require high corrosion resistance.

● Magnesium Sulfate Boards: They are ideal for exterior walls, bathrooms, kitchens, and other humid environments. They are also a great choice for applications requiring high corrosion resistance, such as certain industrial buildings. [Insert a map here indicating the recommended usage areas for magnesium sulfate boards (in green) and magnesium chloride boards (in red) based on humidity levels]

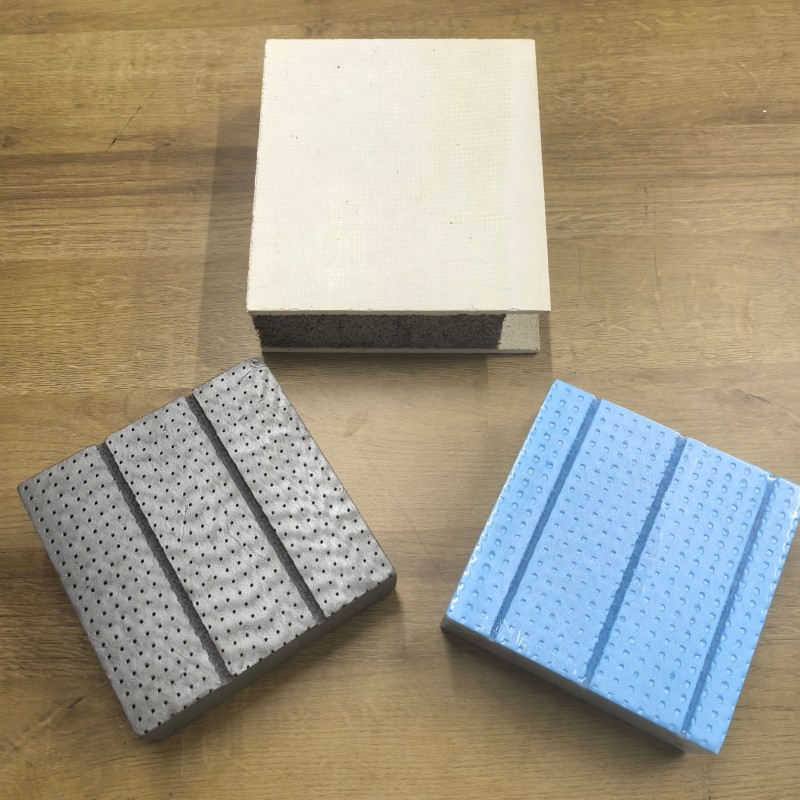

Non - woven Magnesium Oxide Boards vs. Sanded Magnesium Oxide Boards

Flatness

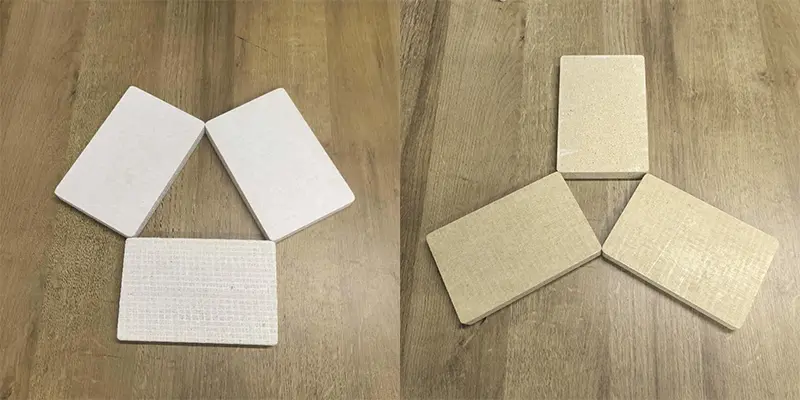

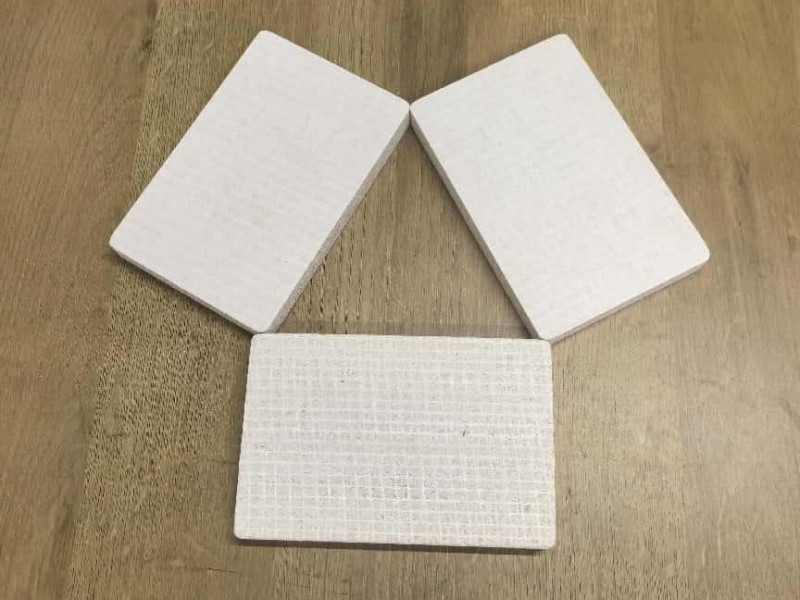

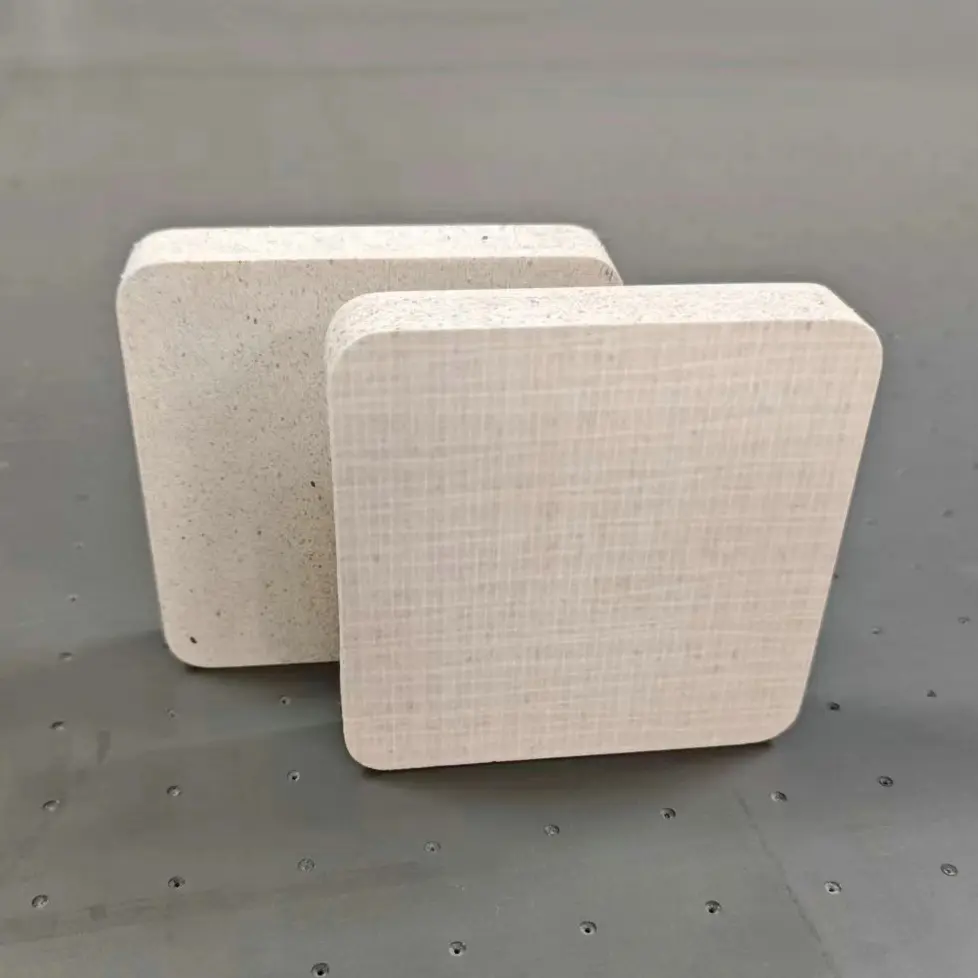

● Non - woven Magnesium Oxide Boards:These boards often have a surface covered with non - woven fabric. While they offer good flexibility and a certain level of strength, their flatness may not be as high as sanded boards. The non - woven fabric can cause a slightly uneven texture, which may not be suitable for applications where a perfectly smooth surface is required.

● Sanded Magnesium Oxide Boards:Sanded boards, on the other hand, undergo a sanding process on their surface. This results in a much higher level of flatness. The surface can be made extremely smooth, with a deviation of less than 0.5mm in thickness across the board in high - quality products. This makes them perfect for applications where a smooth finish is crucial, such as in high - end interior wall finishes or as a base for decorative laminates. [Insert two side - by - side images here, one of a non - woven Magnesium Oxide Board surface and the other of a sanded Magnesium Oxide Board surface to show the difference in smoothness]

Thickness and Surface Finish

● Non - woven Magnesium Oxide Boards:They usually have a relatively consistent thickness, but the surface finish is more textured due to the non - woven fabric. This texture can be beneficial in some applications where added grip or a more natural look is desired, such as in some rustic - style interior designs.

● Sanded Magnesium Oxide Boards: These boards not only have a smooth surface but also a very precise thickness. They can be manufactured to extremely tight tolerances, with thickness variations of less than ±0.2mm. This precision in thickness makes them suitable for applications that require a high level of dimensional accuracy, such as in the construction of high - technologies or in the manufacturing of furniture where precise fitting of panels is essential.

In conclusion, understanding the differences between magnesium sulfate and magnesium chloride boards, as well as non - woven and sanded magnesium oxide boards, is crucial for choosing the right material for your construction or renovation project. Whether it's the moisture - resistance of magnesium sulfate boards, the corrosion - resistance requirements, or the need for a perfectly smooth surface in the case of sanded boards, each type has its own set of advantages that can meet different project needs.

Environmental Building Board

Environmental Building Board Fire-proof Board

Fire-proof Board Sound Resistance

Sound Resistance Termite Resistance

Termite Resistance