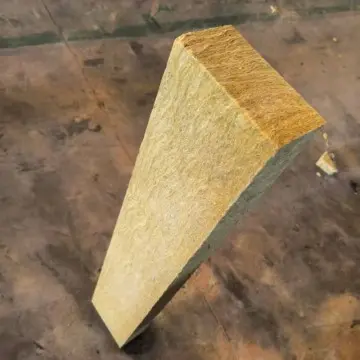

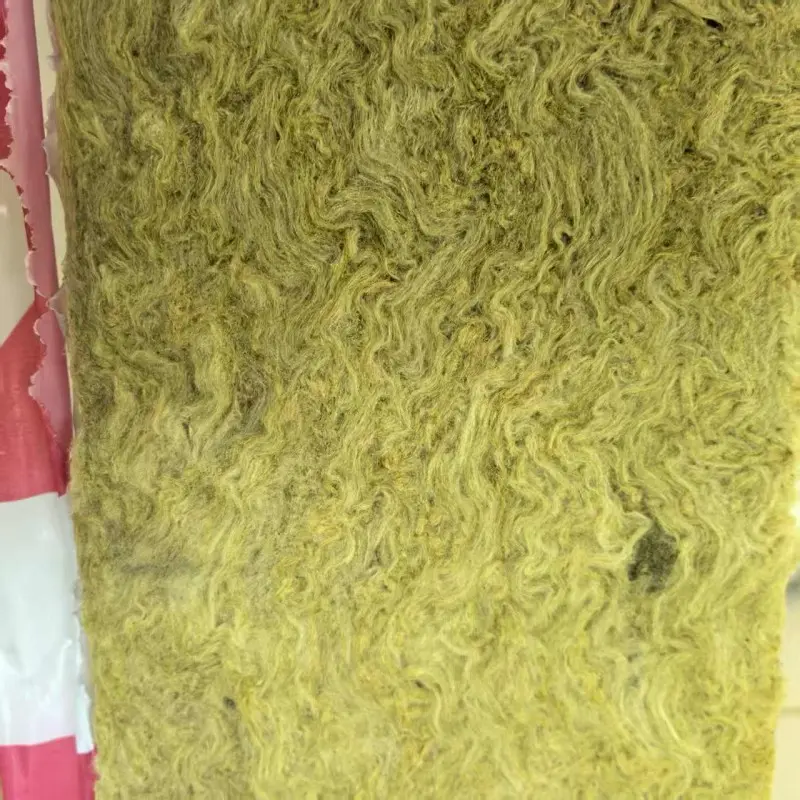

Rock Wool Strip

-

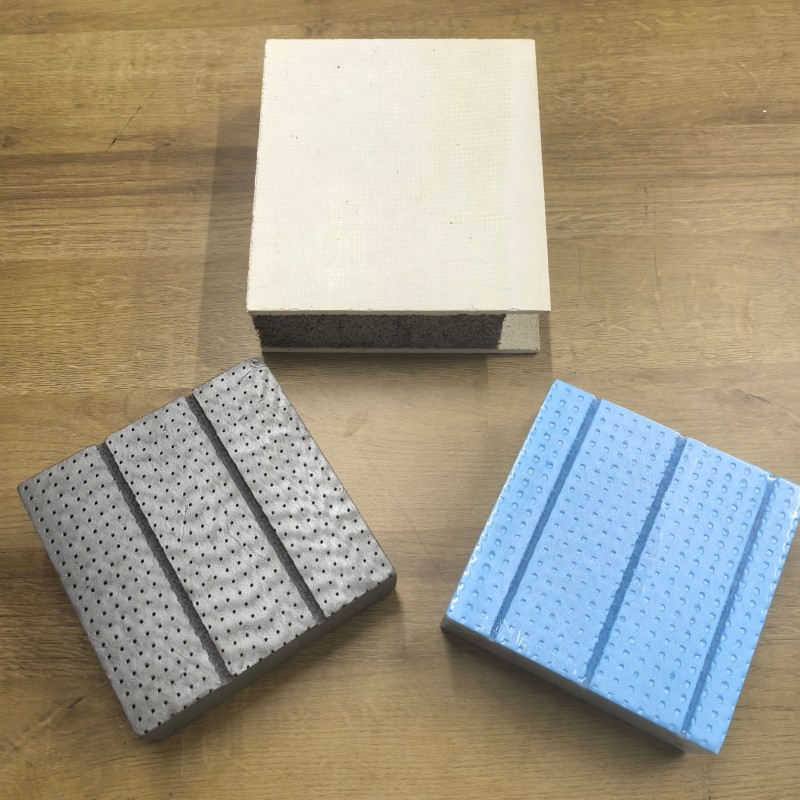

Excellent Compatibility

Fits perfectly with the production processes of composite panels and sandwich panels

-

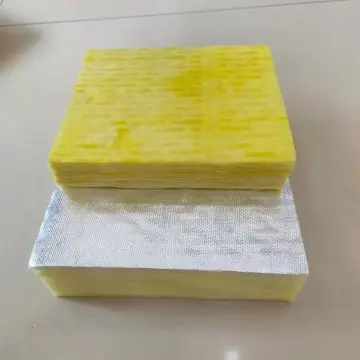

Good fire resistance performance

Class A fireproof materials.

-

Good thermal insulation effect

Internal porosity can effectively insulate against heat.

-

Waterproof and moisture-proof

Moisture-proof and mildew-proof, with a long service life.

-

Environmental protection safety

Basalt is a natural rock and is non-toxic and harmless.

| Non inflammability | Water repellency rate | Heat conductivity coefficient | The contents of potassium oxide and sodium oxide | |

| Standard Request | A1 | ≥98% | ≤0.04 | ≤5.0 |

| Testing result | A1 | 99.5% | 0.039 | 3.36 |

| Determined | Pass | Pass | Pass | Pass |

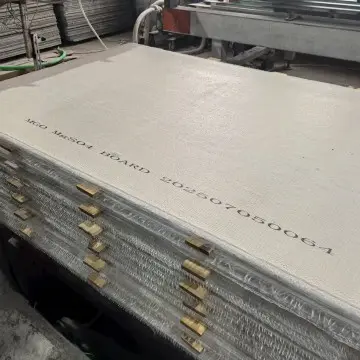

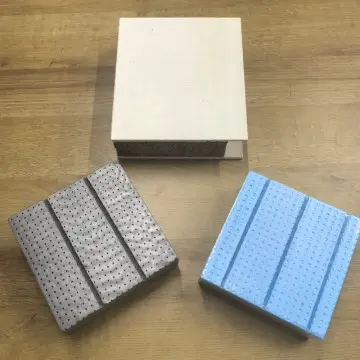

| Thickness(mm) | Shape | Density | L×W(mm) |

| 30mm、50mm、80mm、1000mm、120mm、150mm | Strip (customizable length and width based on panel requirements) | 120kg/m³ and 140kg/m³ | The most common board size is 1200mm (length) × 600mm (width) |

● It can absorb sound and reduce noise, being the preferred choice for sound insulation, suitable for machine rooms and cinemas' partition walls.

● Can be the top choice for industries, resistant to high temperatures and corrosion.

● Can maintain stable performance even in humid environments.

● Grade A fireproofing, essential for exterior and partition walls of high-rise buildings.

● Used as the core insulation and sound absorption layer in composite panels.

● Serves as the core component of sandwich panels, suitable for the renovation and construction of exterior walls, interior partitions, roof panels of residential buildings, commercial buildings and public facilities.

● Applied in the production of fire-resistant composite panels and sound-insulating sandwich panels for special occasions such as high-temperature workshops, machine rooms and noise-sensitive areas (e.g., near airports, highways).

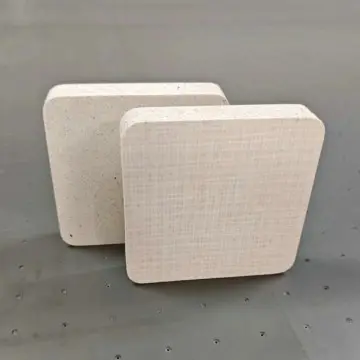

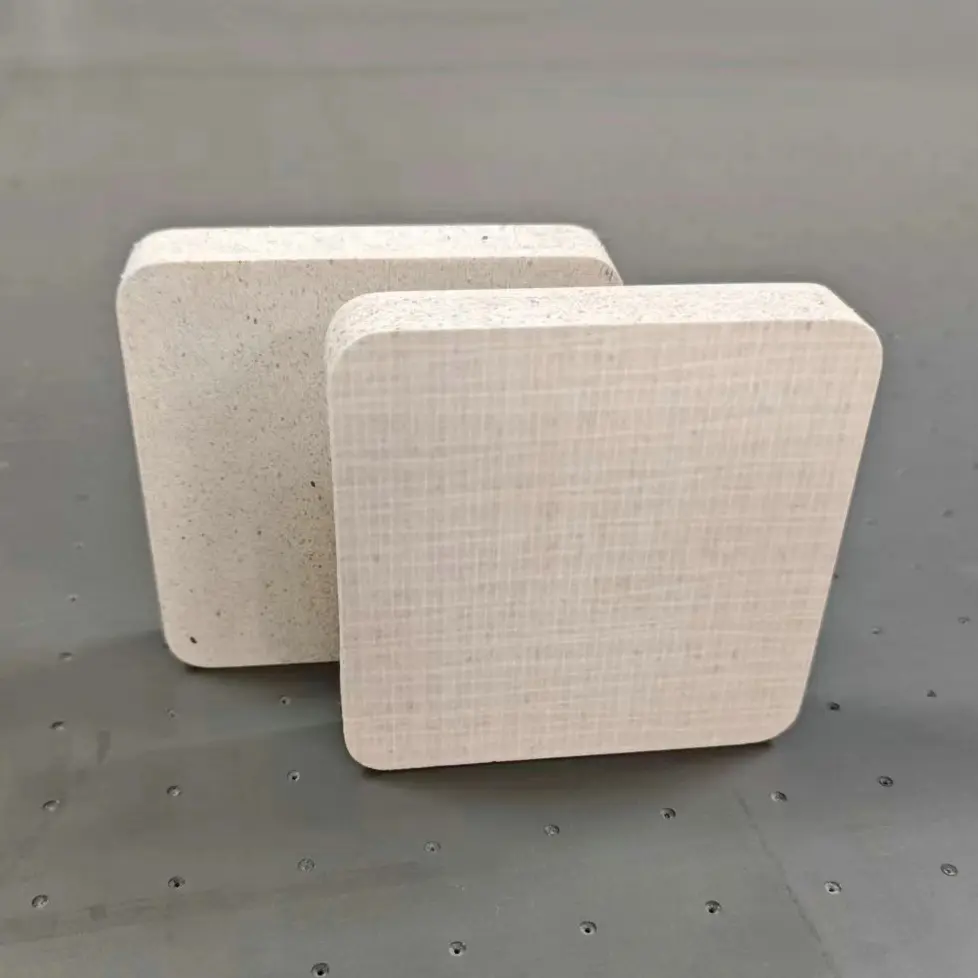

Environmental Building Board

Environmental Building Board Fire-proof Board

Fire-proof Board Sound Resistance

Sound Resistance Termite Resistance

Termite Resistance